Hard Shell has an international reputation for innovation and quality, supplying a wide range of high-performance technical textiles for critical military applications to diverse markets around the world. Woven knitted, dyed coated, and finished fabrics form the basis of our product range, supported by superior specifications, raw materials and efficient component design. When it comes to body armor, we believe that there is no room to compromise on safety. Hard Shell relies on innovation and advanced technology to manufacture body armor with tried and tested materials. One of those materials is Aramid which stands out with its unmatched strength and resilience.

In simple terms, Aramid is a synthetic fiber known for its remarkable strength and heat resistance. Its various applications include body armor, aerospace, and sports equipment. The molecular structure of an Aramid fiber consists of long chains of aromatic polyamides, giving it the strength that it is known for. You will be surprised to know that this unique arrangement responsible for Aramid fiber's exceptional tensile strength can make it five times stronger than steel of the same weight.

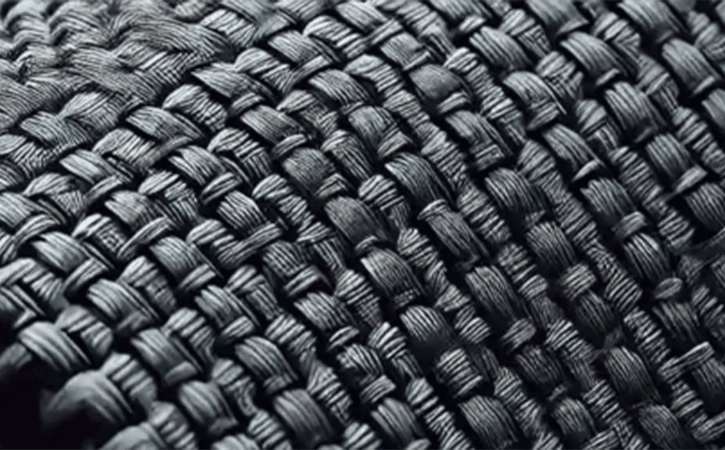

Weaving is the technique that turns unprocessed Aramid fibers into a robust ballistic fabric. At Hard Shell, advanced looms are utilized to delicately weave Aramid fiber threads to form a dense structure resistant to ballistic threats. For ballistic materials, the most popular weaving patterns are plain weave, twill weave, and satin weave. Every pattern has its unique characteristics and differs in strength, flexibility, and weight.

A plain weave creates a simple but robust fabric by having each warp yarn pass alternately over and under each weft yarn. If durability is what you are looking for, this weave pattern's exceptional abrasion resistance and uniform strength distribution make it the perfect choice.

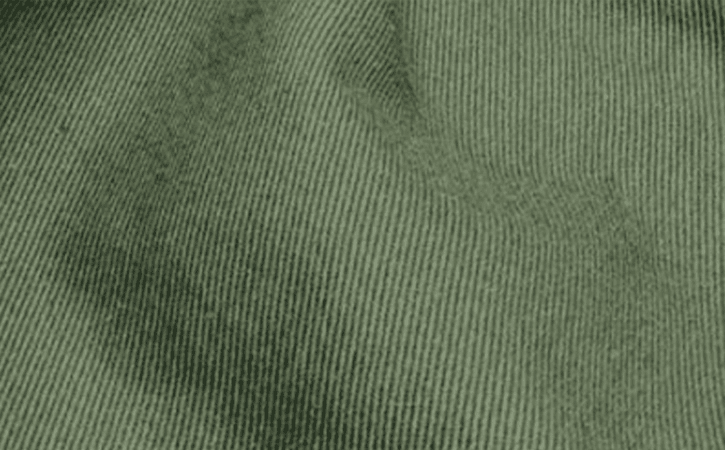

Twill weave creates a diagonal pattern, in which filling threads pass over one and under two or more warp threads. While keeping the high tensile strength of the fabric intact, this method of weaving improves the fabric's flexibility and drapability. Ballistic vests and helmets often use twill weave fabrics to provide the wearer with the best possible comfort and movement.

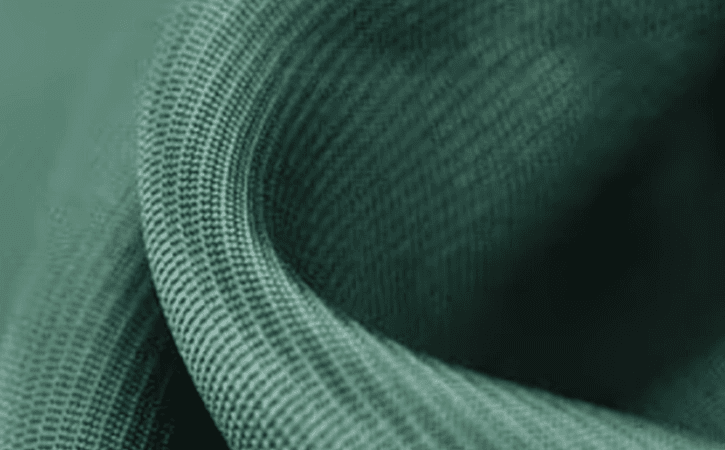

Stain weave, which is produced by floating warp strands across several weft yarns, has a glossy appearance and a smooth surface. Satin weave fabrics are less dense than plain or twill weaves. However, they drape better and provide superior flexibility, making them good for applications where comfort and style are prioritized over protection.

End to end control

Precision Crafted for Your Needs

A Global Shield of Confidence

Sustainability at the Core of Safety